Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

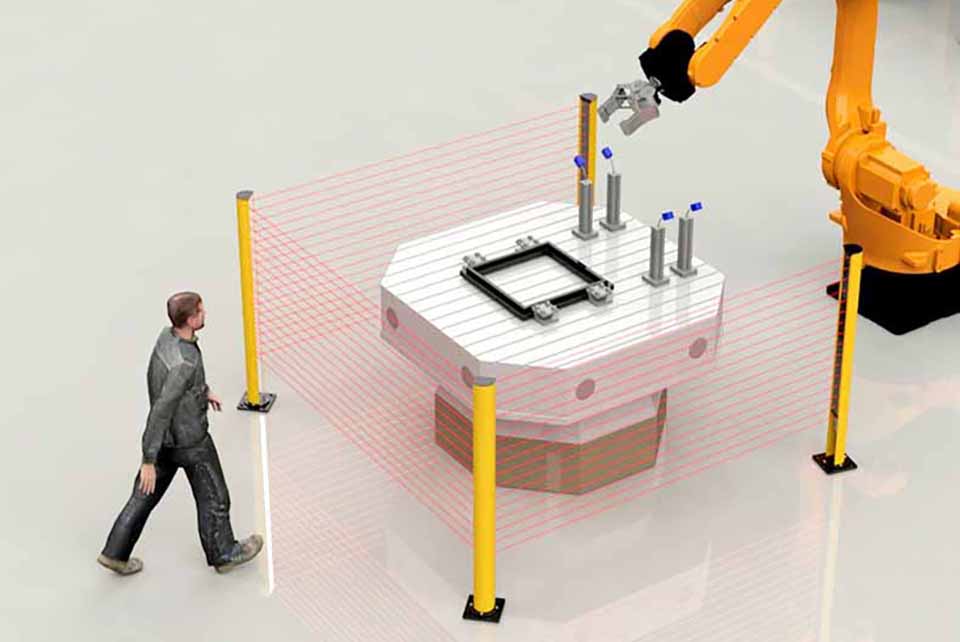

These advanced safety devices use an array of infrared light beams to create an invisible safety barrier around dangerous machinery, ensuring that no one can accidentally enter a hazardous area without being detected. This guide will walk you through everything you need to know about safety light curtains, from how they work to their applications and benefits.

A light curtain is an advanced safety device designed to protect individuals from hazardous areas by using an array of infrared light beams. When these beams are interrupted, the system triggers a stop or alarm, preventing accidents. The light curtain system is an essential part of many industrial safety solutions, offering a versatile range of light curtain options to fit different needs.

Safety light curtains work by emitting multiple beams of infrared light across a designated area. If an object or person interrupts any of these beams, the system sends a signal to stop the machinery, ensuring immediate safety. This interruption is detected by the control system, which can either externally or internally signal an appropriate response. This safety function is crucial to maintaining a high level of safety performance in industrial environments.

The use of light curtains in safety applications is critical in environments where human-machine interaction poses risks. These devices offer several benefits:

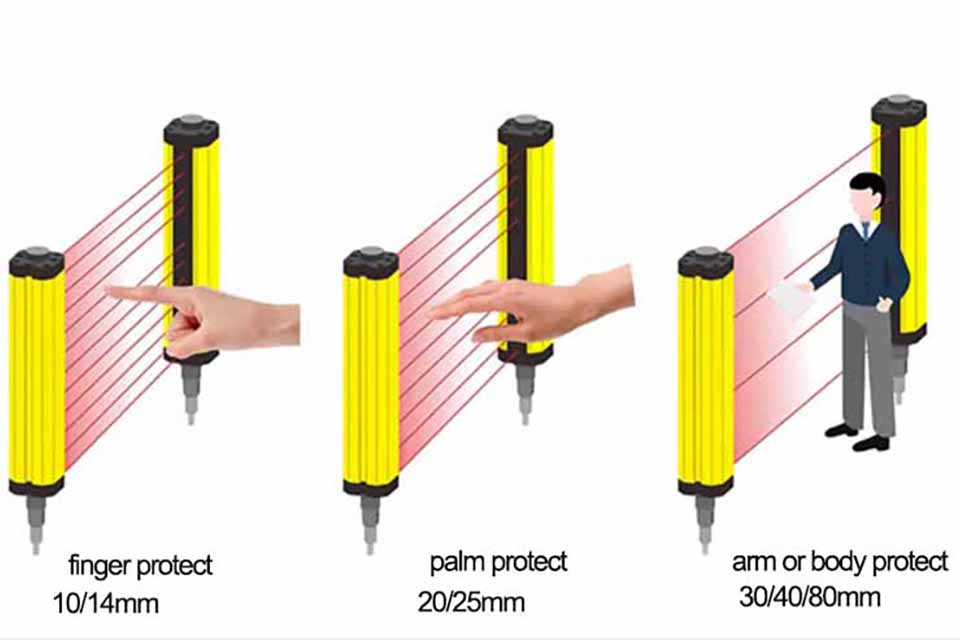

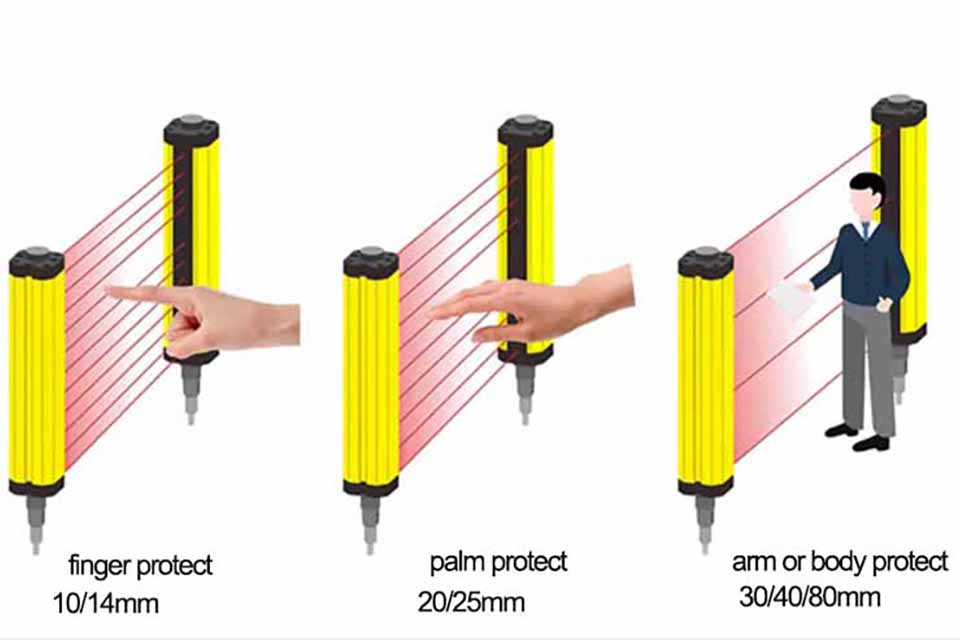

There are several types of safety light curtains to choose from, depending on specific needs:

When selecting a light curtain, consider these key features:

Choosing the right safety light curtain involves considering the specific needs of your application. Factors to consider include:

Proper installation and maintenance are critical to ensure the effectiveness of light curtains:

While both safety light curtains and safety laser scanners provide protection, they have different applications. Light curtains are ideal for straightforward safety barriers, while laser scanners offer more flexibility in detecting objects in three-dimensional spaces.

Safety light curtains are used in various industries, including:

Implementing light curtains can significantly enhance both safety and productivity in industrial settings. By reducing the need for physical barriers, these systems allow for more efficient workflows while maintaining high safety standards.

For more information on light curtains and related safety devices, visit New Star Sensor’s Safety Light Curtain Sensor and explore their Industrial Safety Light Curtain Sensor.

Incorporating light curtains into your safety system can revolutionize your approach to protecting workers and increasing efficiency. Whether you’re new to these devices or looking to upgrade your current setup, understanding their capabilities and applications is the first step toward a safer workplace.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.